-

[0] Quote Cart

- Log In

- Upload your RFQ File

- Get quoted for unfound product

My Quote Cart - Quick Quote

-

Product Categories

- Fastening and Joining Fastening and Joining

- Tooling Components Tooling Components

- Quick Release Pins - Locking Pins Quick Release Pins - Locking Pins

- Locating Components Locating Components

- Clamping technologies Clamping technologies

- Lifting Solutions Lifting Solutions

- Knobs, Cranks, Handles, Levers, Hand Wheels Knobs, Cranks, Handles, Levers, Hand Wheels

-

Bushings

Bushings

Bushings

- Press-Fit Drill Bushings

- Removable Drill Bushings

- Embedment Bushings

- Gun Drill Bushings

- Oil-Groove Bushings

- Extra Thinwall Bushings

- TYPE AF - Air Feed Drill Bushings

- Template Bushings

- Toolholder Bushings

- Titanium Nitride Bushings (TiN)

- Tungsten Carbide Bushings

- Type CB, Circuit Board Drill Bushings

- EZ Cast Bushings

- Power Transmission - Oilite Bushings

- Drill Bushings Accessories

- Hardware Hardware

- Industrial Supplies Industrial Supplies

- Modular Hose Systems Modular Hose Systems

- Liquidation Liquidation

- Order Catalog

- Stock Control

- Home>

- Catalog>

- Tooling Components>

- Quick Change Fixturing technologies>

- Ball Lock System®>

- Quick change Kits

Quick change Kits

Everything You Need to Change Fixtures in Less Than One Minute

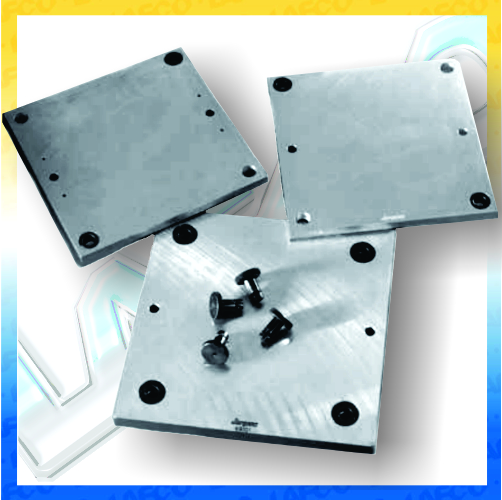

The Jergens Ball Lock® Quick Change Kits speed fixture changeover in all types of manufacturing operations. Each kit includes two aluminum fixture plates with 2 primary liner bushings installed; one steel subplate with receiver bushings installed, and four 20mm Ball Lock® shanks with working loads of 3000 lbs. each. While one fixture plate is on the machine, the operator can load parts on the other. This minimizes downtime for true set-up reduction. To enable the subplate to be mounted on a slotted table without the need to indicate the subplate, sine fixture keys can be used. The sine fixture key reamed holes are oriented parallel to the receiver bushings on the subplate and to the liner bushings on the fixture plate. These also allow the fixture plate to be mounted on a toolroom mill without the need to indicate it. This is extremely useful when machining location points on your fixture